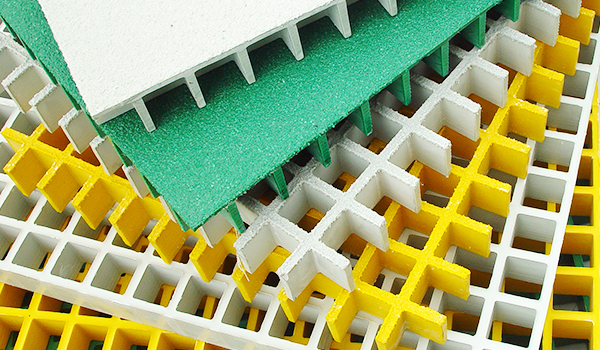

Lighter but stronger

FRP is 70% lighter than steel, with superb weight ratio.

FRP grating can even be strong enough to withstand vehicle loads while weight is less than steel grating.

FRP grating can even be strong enough to withstand vehicle loads while weight is less than steel grating.

Product

Product Email

Email Phone

Phone